Although you may not be aware, semiconductors are found in almost every aspect of our daily life.

What role does LG Chem play in the process of making semiconductors, something so close to our lives?

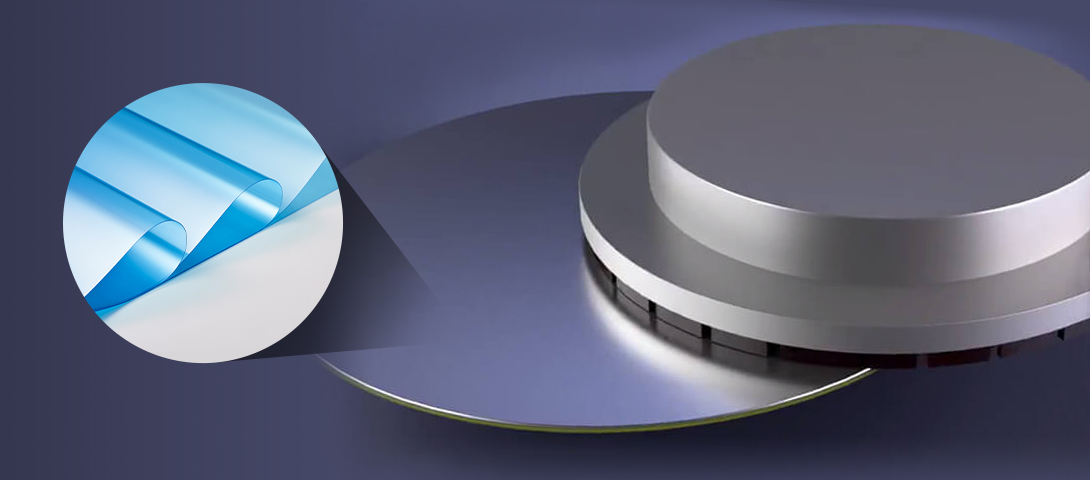

One of the key characteristics of semiconductors is that they must be extremely thin.

To achieve this, it is necessary to reduce the thickness by thinning the back side of the wafer during a post-process called "back grinding."

This is when LG Chem's BGT (Backside Grinding Tape) plays a critical role.

The first step in back grinding is tape lamination,

which attaches a blue tape with adhesives on the front of the wafer to protect the pattern surface during the process.

BGT prevents a penetration of silicon powder generated in the backgrinding process and cleaning agent used during the process,

while protecting the wafer from being damaged or distorted by the grinding force.

After the back grinding process, UV rays are irradiated on the tape surface to minimize adhesion, then the tape attached to the wafer is removed.

BGT provide high adhesive strength to prevent gaps or air bubble between wafers and tapes in the backgrinding process.

Once it completes the process, it releases it without a problem.

LG Chem's BGT is the unsung hero that allows semiconductors to maintain their stable forms.

![[Polymer Catalysts, Process Catalysts] Enhancing the Value of Petroleum](/upload/file/lifein-lgchem/catalyst_thumbnail_670[0].jpg)