DAF

Ultra-Thin Film Adhesive Materials for Semiconductor Package Stacking and Thinning

DAF (Die Attach Film) is an ultra-thin film adhesive used in semiconductor packaging processes to bond semiconductor chips to substrates or to other chips. By integrating the dicing tape—which supports the wafer during singulation—and the die bonding tape—which attaches the chip to the substrate—DAF simplifies the packaging process. It is an essential material in the back-end processes of high-density semiconductors such as flash memory, enabling package stacking and thinning thanks to its excellent reliability and processibility.

Applications

Product Functions and Structure

• Stable bonding quality ensured through uniform thickness control

• Improved reliability through excellent gap-filling characteristics and void-free bonding after die attach cure

• High adhesion strength enables highly reliable bonding to various substrates and chips

• Excellent heat resistance and reliability for high-temperature processes and thermal cycling environments

• Easy pick-up and excellent processability

• Compatible with both blade and laser dicing processes

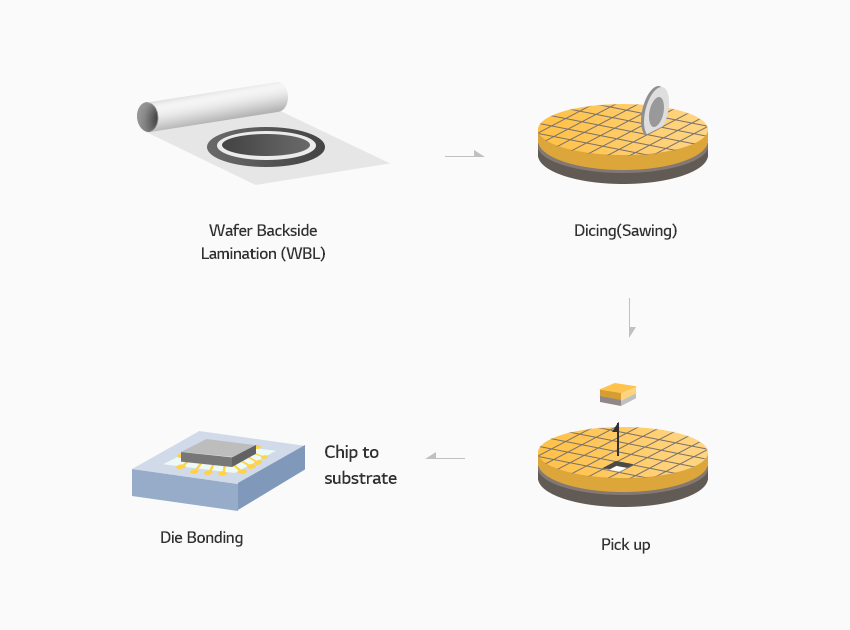

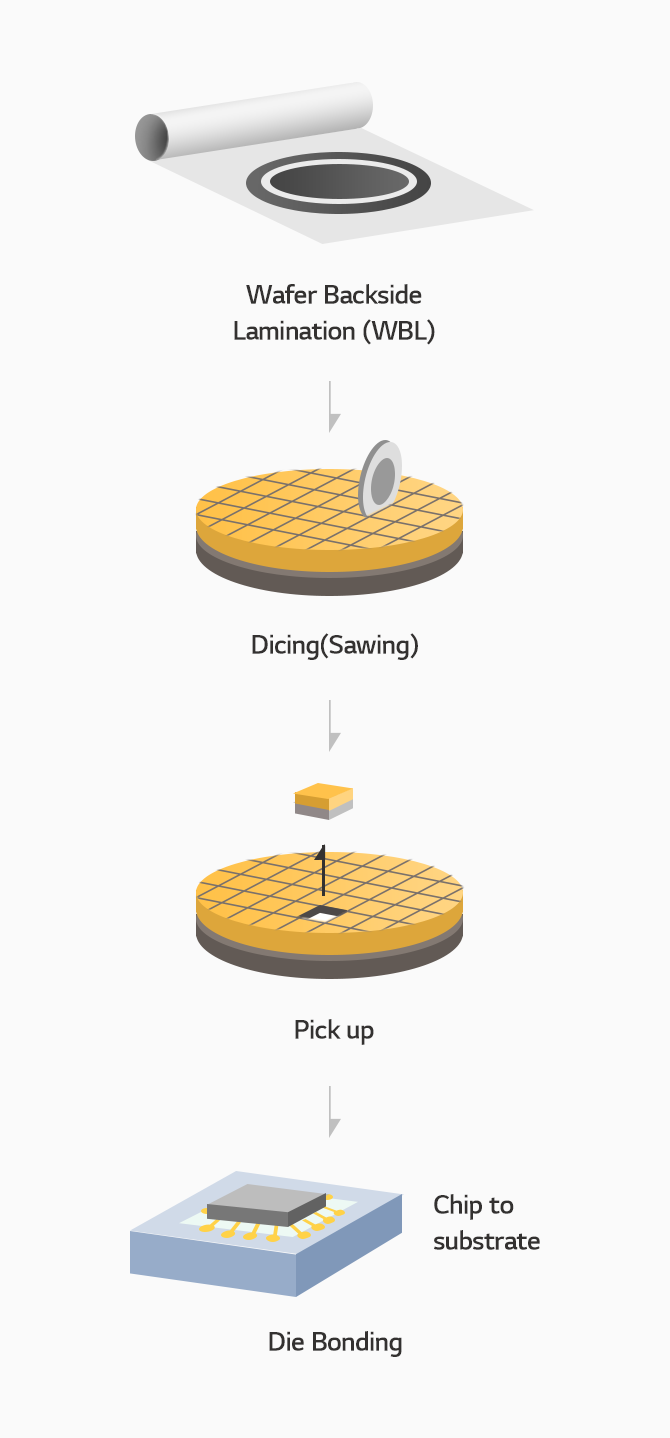

DAF Process