Brand Introduction

and a healthier future made together by Earth and

LG Chem, LETZero

Eco-friendly Materials Brand LETZero

LG Chem has published a product book containing LG Chem’s Eco-Friendly Materials

Brand LETZero products.

LETZero is a master brand that integrates eco-friendly materials such as 'Recycle products' made from reprocessed waste plastics, 'Bio materials' made from bio-based renewable materials, and 'Biodegradable materials' that can be decomposed by living organisms like bacteria.

We introduce LG Chem’s eco-friendly product line for sustainable environment and

future through Product Book.

Products Overview

Our main product lines include recycled (Recycled) materials made of waste plastic, bio materials derived from renewable plant-based materials, and biodegradable materials that can be decomposed by living organisms like bacteria.

With LETZero, LG Chem will embark on our journey toward zero for a better future of humanity.

Recycled Products

Manufacturing Process

Mechanical Recycling

Chemical Recycling

Compostable Products

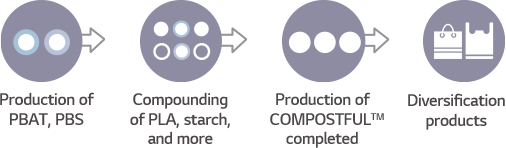

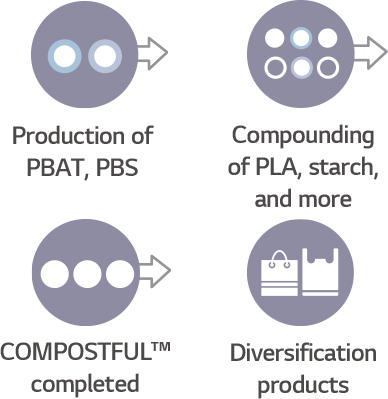

Manufacturing Process

COMPOSTFULTM

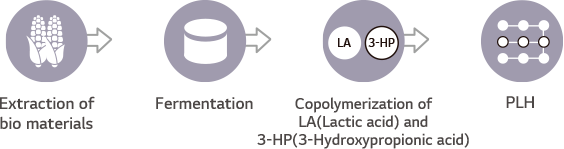

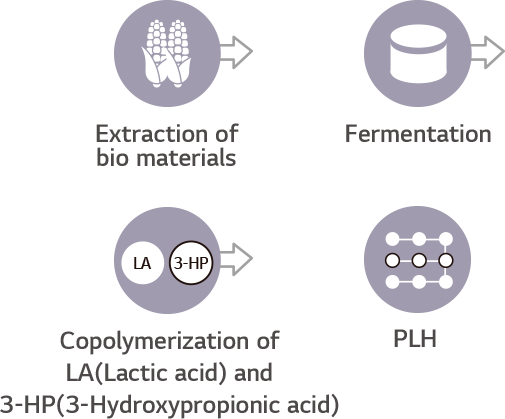

PLH

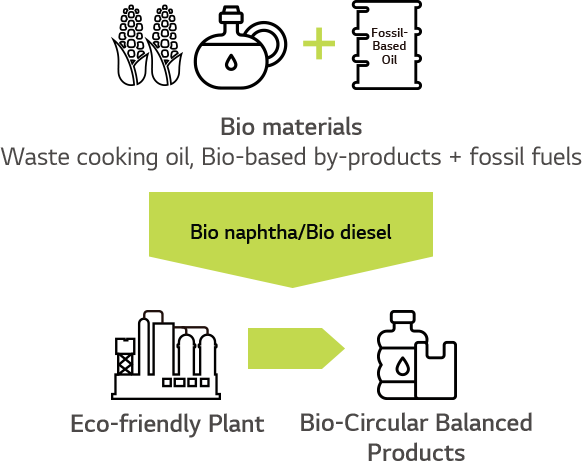

Bio-balanced Products

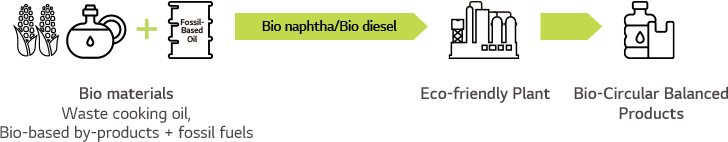

Bio-Circular Balanced (BCB) products

Manufacturing Process

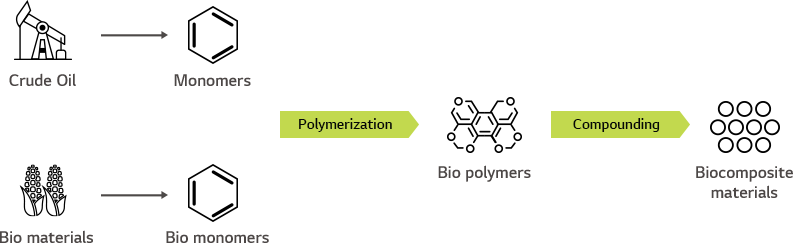

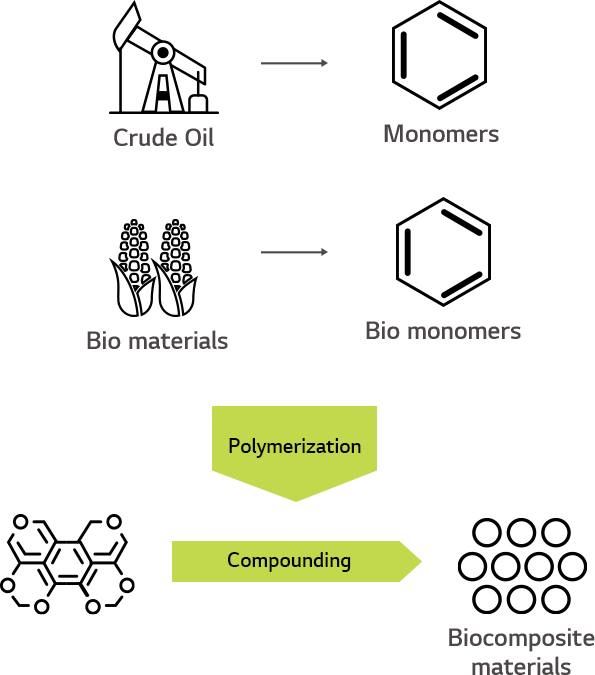

Bio-based products

Manufacturing Process

Application of LETZero Materials

PCR PC X LG Electronics Global Best Shop POP

Related Links

Bio-Circular Balanced BR, POE X Descente sneakers insole

PCR PC X KEVIT (Korea Electric Vehicle Infrastructure Technology) Electric Vehicle Charger

Related Links

Bio-Circular Balanced ASA X Hanssem Deco Sheet

Related Links

PCR PE X LG Electronics Packaging Vinyl

PCR PVC X Nukak Recycled Goods

PCR PC, ABS X Seoul City Color of the Year Traditional Sobang

PCR PC X Seoul City Smart Shelter

BCB SAP X Amons Dog Pad

PCR PC, ABS X LG U+ & KT Set-top Box, Remote Control

PCR PC, ABS Compound X LG Group Employee ID Card

PCR PC X Cafeteria Transparent Divider

PCR PC X DrawingMary Artist Collaboration Smartphone Case

For business inquiries regarding LG Chem's eco-friendly materials brand, see below the product for Ask questions to reach out to a person in charge.

![LG Chem's journey to low carbon polymer, Polycarbonate [LG Chem Tech] Eco-friendly Materials Brand LETZero LG Chem](/asset/images/common/sustainability/new/youtube/17.jpg)

![재활용 플라스틱부터 생분해성 신소재까지, 지구를 생각하는 LG화학의 이유 있는 도전 [LG Chem Tech] Eco-friendly Materials Brand LETZero LG Chem](/asset/images/common/sustainability/new/youtube/16.jpg)

![Why is LG Chem developing recycled plastics(PCR ABS)? [LG Chem Tech] Eco-friendly Materials Brand LETZero LG Chem](/asset/images/common/sustainability/new/youtube/15.jpg)

![폐가전제품이 재활용 플라스틱이 된다? PCR ABS 만드는 과정 대공개! 멍 때리고 보는 엘화 팩토리 Ep.01 PCR ABS [LG Chem Tech] Eco-friendly Materials Brand LETZero LG Chem](/asset/images/common/sustainability/new/youtube/2.jpg)

![친환경 소재? 생분해성 플라스틱? 생분해성 신소재의 탄생! LG화학x안될과학 [LG Chem Tech] Eco-friendly Materials Brand LETZero LG Chem](/asset/images/common/sustainability/new/youtube/6.jpg)

![LG화학이 재활용 플라스틱을 개발하는 이유! PCR ABS 기술지원 & 컬러디자이너 인터뷰 [LG Chem Tech] Eco-friendly Materials Brand LETZero LG Chem](/asset/images/common/sustainability/new/youtube/7.jpg)

![버려진 플라스틱이 PCR ABS로 새롭게 탈바꿈하는 과정, 최초 공개합니다! 프로출장러가 간다EP.01 [LG Chem Tech] Eco-friendly Materials Brand LETZero LG Chem](/asset/images/common/sustainability/new/youtube/9.jpg)