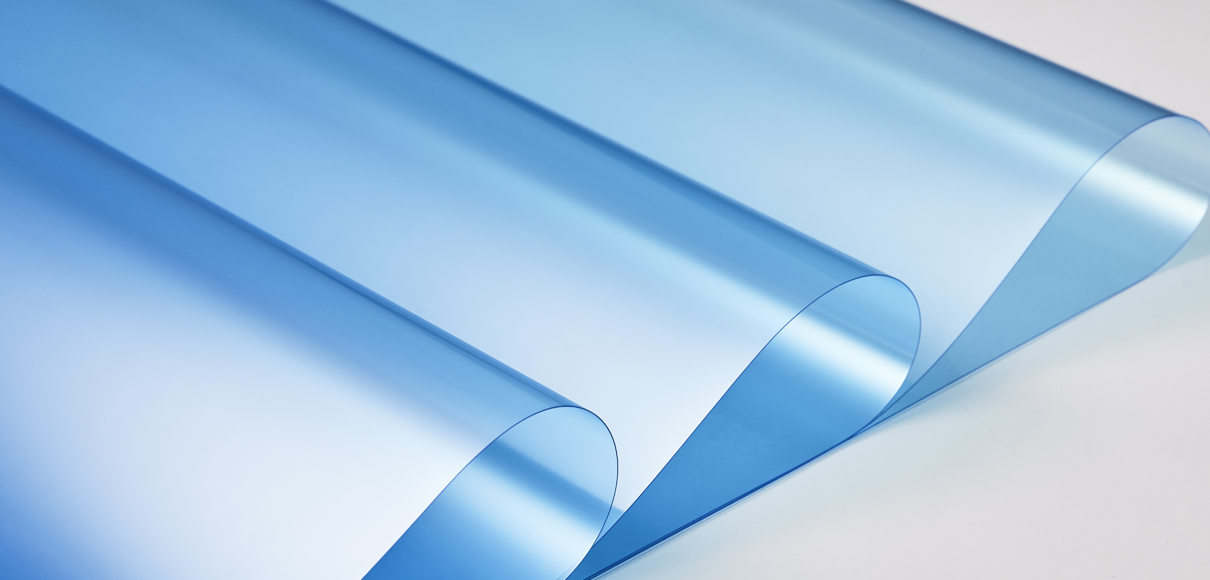

BGT

背面磨削时保护 Wafer 表面的必备材料

BGT(背磨胶带)是在晶圆形成IC电路后,于背磨(Back Grinding)工艺中,为保护晶圆表面而贴附的胶带。它直接贴附在电路面上,防止基板损伤和表面污染,并提高研磨工艺的精度。 特别是凭借优异的物理和化学特性,在工艺过程中稳定保护晶圆图案面及芯片,有助于实现高质量封装。

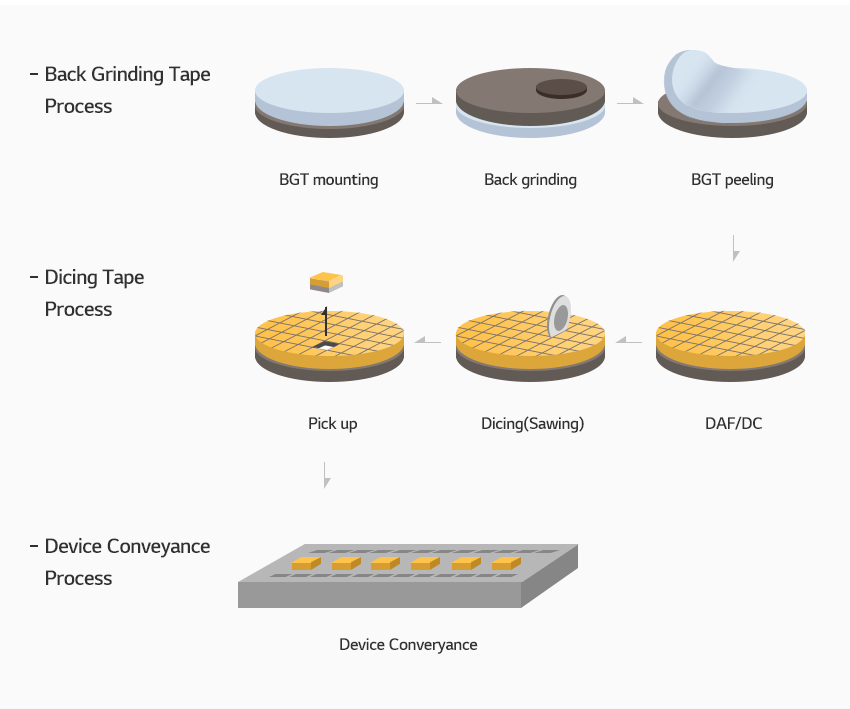

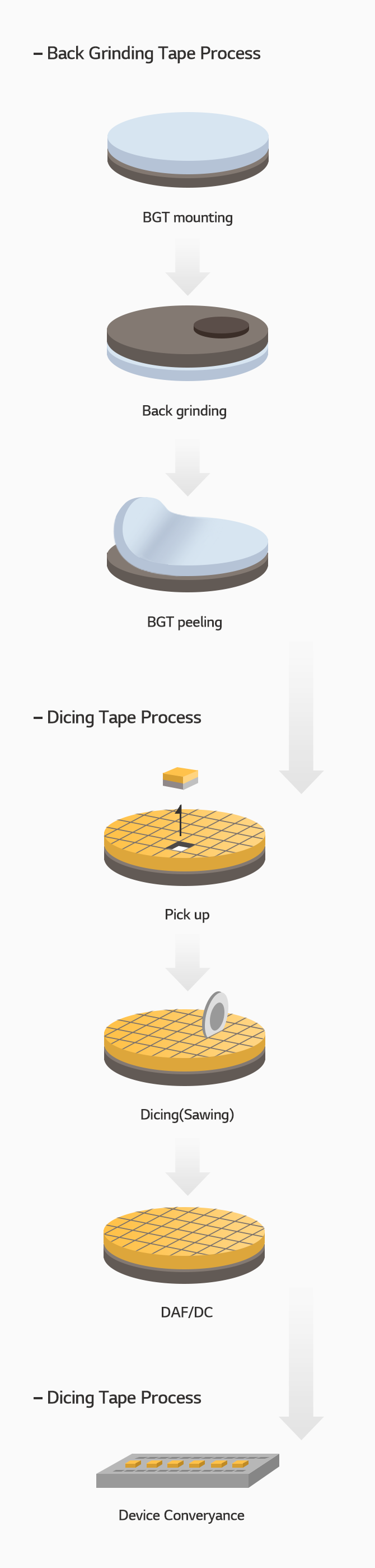

用途

产品功能

• 通过优异的TTV(总厚度变化)控制,保持均匀厚度

• 保护图案面并防止Die移动(Die Shift),避免芯片损伤

• 吸收背磨过程中产生的冲击和异物,提高工艺稳定性

• UV曝光后易于去除,可实现无残留的干净分离

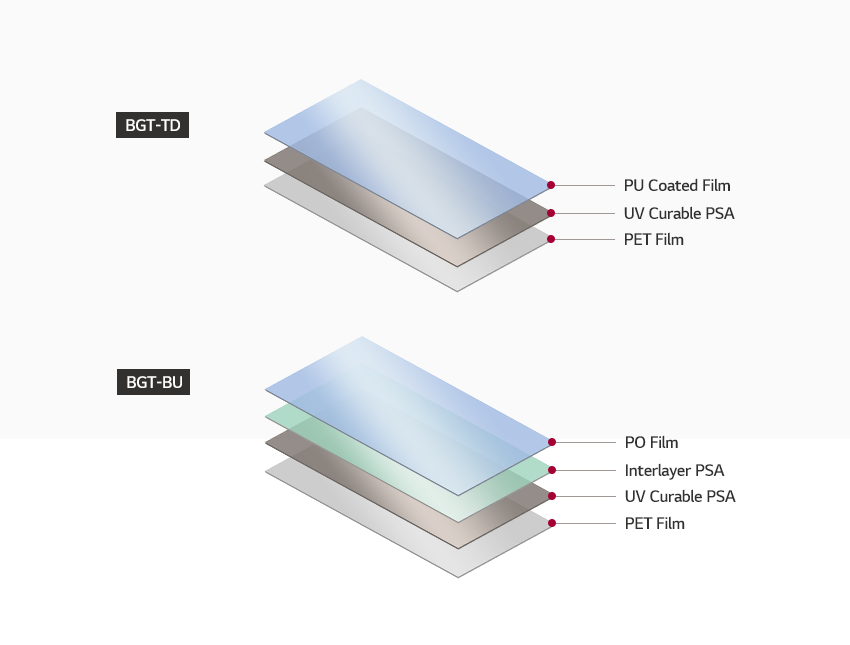

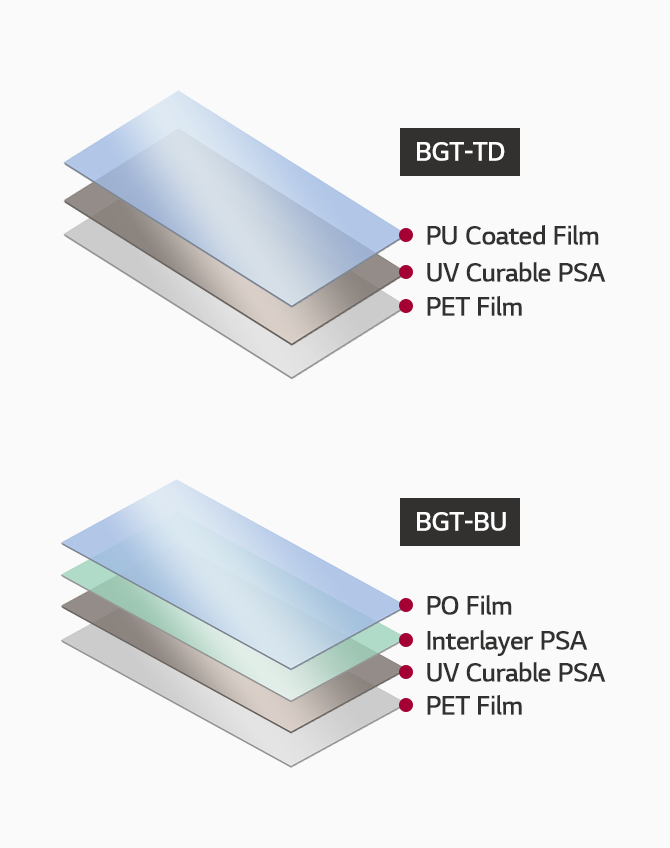

产品结构

![[BGT] 陪伴晶圆直到变得更加完美<br /> BGT Backside Grinding Tape LG Chem 尖端素材 背面磨削时保护 Wafer 表面的必备材料](/upload/file/lifein-lgchem/BGT_main[1].jpg)