CCL/PPG

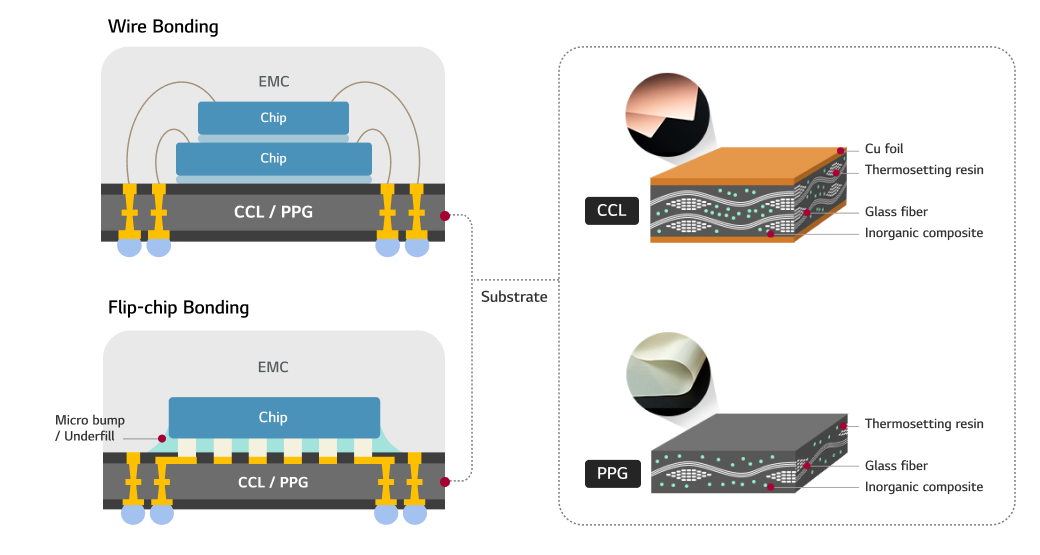

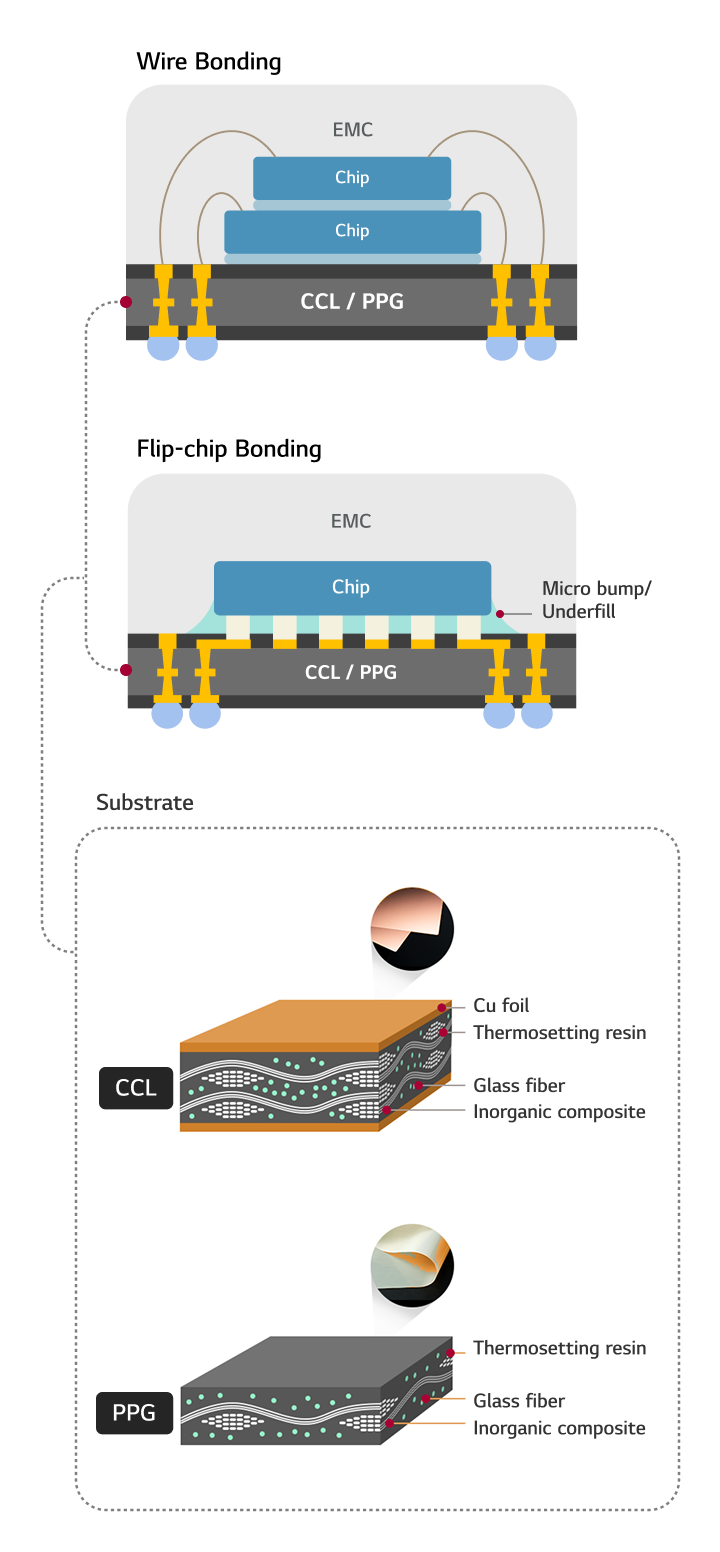

Key materials of semiconductor IC package substrates

CCL, or Copper Clad Laminate, is a composite material consisting of copper foil laminated on both sides of an insulating substrate. It serves as a key material in IC package printed circuit boards (PCBs), providing electrical connectivity, insulation, and mechanical support for electronic devices. LG Chem offers advanced CCL solutions designed to meet the evolving demands of semiconductor packaging technologies, including miniaturization, thinning, and high performance. With excellent electrical properties and high reliability, our CCL products are optimized for various applications and core material characteristics. Through a diverse product lineup tailored to specific needs, we help customers overcome technical challenges and establish a stable material foundation for next-generation electronic device development.

Features

Excellent insulation performance

Thermal and mechanical stability

Superior processability and durability

Moisture and chemical resistance

Applications

Product functions and structure

• Offers warpage control solutions based on low thermal expansion and low stress characteristics

• Enables lightweight and durable high-strength thin substrates for compact device designs

• Implements substrates with low dielectric constant (Low Dk) and low dissipation factor (Low Df) for high-speed signal transmission