NCC

Achieving the best energy efficiency in the world

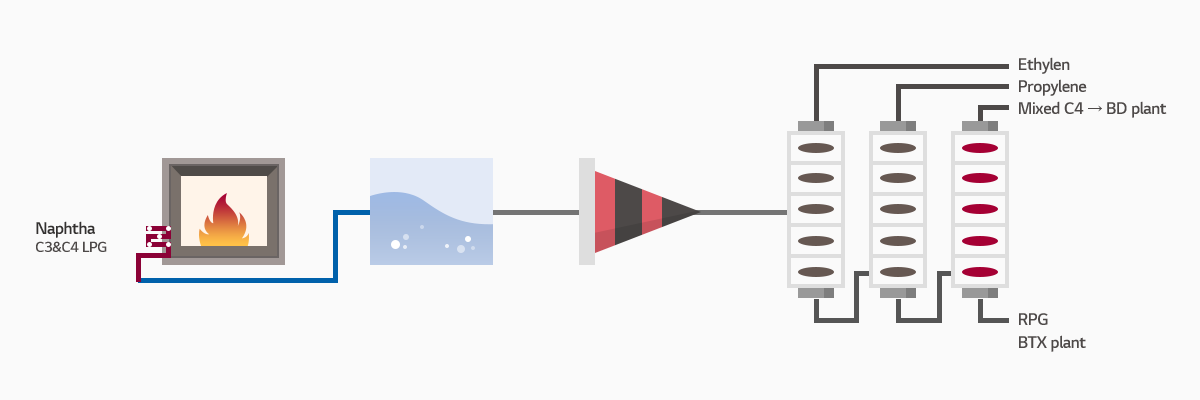

NCC is a facility for producing basic petrochemicals such as ethylene and propylene, which are the base materials for petrochemistry, by cracking naphtha at high temperature. Naphtha is obtained by refining crude oil. LG Chem has secured excellent cost competitiveness by achieving the best energy efficiency in the world.

Applications

Competitiveness

Cracker energy efficiency of 95%

An in-house power generator and waste heat recovery system

The best global NCC energy company in the world

Process

![[NCC] Obtaining raw materials for plastic from petroleum NCC Naphtha Cracking Center LG Chem Petrochemicals Achieving the best energy efficiency in the world](/upload/file/lifein-lgchem/NCC_main.jpg)