PVC

Versatile Solutions for Construction and Consumer Goods

PVC (Polyvinyl Chloride) is a widely used general-purpose thermoplastic that can be customized in terms of hardness, durability, and other properties by adjusting the additives used during processing. Leveraging these characteristics, PVC is extensively used in a variety of applications, including flooring, window frames, pipes, interior films, and more. LG Chem has developed HRTP (Heat-resistant and Recyclable ThermoPlastic), an innovative high-molecular-weight PVC with excellent durability and heat resistance, offering solutions for electric vehicle charging cables, automotive high-heat-resistant wires, high-quality artificial leather, and more. Additionally, LG Chem is leading the eco-friendly trend with BCB PVC (Bio-Circular Balanced PVC), which uses bio-based raw materials, and PCR PVC (Post-Consumer Recycled PVC), which incorporates recycled materials.

1. General PVC – Versatile and High-Performance Material

Features

- Durability Minimal deformation even after long-term use

- Corrosion Resistance Resistant to chemicals

- Chemical Stability Stable in various environments

- Flame Retardancy Reduces fire risk

- Processability Can be molded into various shapes

Key Applications

2. HRTP PVC – Next-Generation Material with Ultra-High Molecular Weight

Features

- Ultra-High Molecular Weight Enhanced properties due to world-class molecular weight

- High Performance Excellent heat resistance, cold resistance, durability, and mechanical properties

- Flexibility Capable of producing highly flexible, low-hardness soft products

- Composite Material Compatibility Enables combination of various properties

- High Flame Retardancy Minimizes fire risk

- Eco-Friendly Non-crosslinked structure allows for recycling

Key Applications

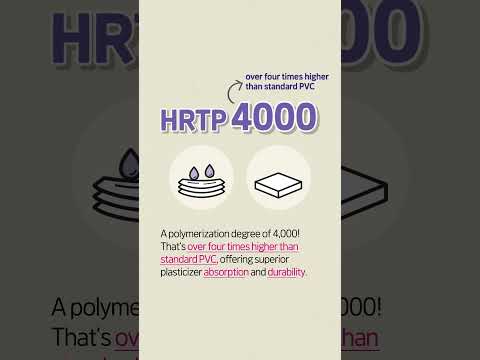

Competitive Edge: HRTP 4000 – The Standard for Next-Generation PVC

- World-class ultra-high molecular weight and plasticizer absorption capability

- Recyclable, high-heat, and flame-retardant material

- Enhanced heat resistance, cold resistance, durability, and mechanical properties

- Provides a matte finish and excellent tactile feel

- Improved processability: Enables production of highly flexible, low-hardness soft products

Application Example: Electric Vehicle Charging Cables

- Superior heat resistance and flame retardancy compared to conventional materials

- Excellent flexibility, allowing easy handling during charging

3. BCB PVC – Leading the Eco-Friendly Trend with Bio-Circular Balanced PVC

Features

- Bio-Based Raw Materials : Utilizes renewable resources such as used cooking oil(UCO), palm fatty acid distillate(PFAD), and animal fats

- Equivalent Performance : Maintains the same performance as conventional PVC while being eco-friendly

- ISCC Certification: : Internationally recognized eco-friendly certification

Competitive Edge

- Eco-Friendly Consumer Choice : Provides consumers with a value-driven purchasing experience

- Enhanced Corporate Image : Strengthens ESG (Environmental, Social, Governance) management for companies

- CO2 Reduction : Contributes to a sustainable future by reducing carbon emissions

4. LG Chem PVC Product Lineup Comparison

| Category | General PVC | HRTP PVC | BCB PVC |

|---|---|---|---|

| Features | Durability, corrosion resistance, flame retardancy | Ultra-high molecular weight, high performance, heat resistance, flexibility | Bio-based, eco-friendly, equivalent performance |

| Key Applications | Wire insulation, pipes, synthetic leather, etc. | EV charging cables, automotive wires, etc. | Construction materials, flooring, etc |

| Competitive Edge | Versatility and cost-effectiveness | High performance, flame retardancy, recyclability | Eco-friendliness, ESG management, CO2 reduction |

| Category | Features | Key Applications | Competitive Edge |

|---|---|---|---|

| General PVC | Durability, corrosion resistance, flame retardancy | Wire insulation, pipes, synthetic leather, etc. | Versatility and cost-effectiveness |

| HRTP PVC | Ultra-high molecular weight, high performance, heat resistance, flexibility | EV charging cables, automotive wires, etc. | High performance, flame retardancy, recyclability |

| BCB PVC | Bio-based, eco-friendly, equivalent performance | Construction materials, flooring, etc | Eco-friendliness, ESG management, CO2 reduction |

![[Eco-friendly PVC] Worry-Free Rainy Season with Rain Boots<br /> PVC Polyvinyl Chloride LG Chem Petrochemicals Versatile Solutions for Construction and Consumer Goods](/upload/file/lifein-lgchem/PVC_0908[0].jpg)

![[PCR-PVC] Going Green in the Music Industry <br /> PVC Polyvinyl Chloride LG Chem Petrochemicals Versatile Solutions for Construction and Consumer Goods](/upload/file/lifein-lgchem/PVC_0712[1].jpg)

![[PVC] Preparing for the new year with a diary PVC Polyvinyl Chloride LG Chem Petrochemicals Versatile Solutions for Construction and Consumer Goods](/upload/file/lifein-lgchem/PVC_diary_main[1].jpg)

![[PVC] Adding analogue sensibilities to LP records PVC Polyvinyl Chloride LG Chem Petrochemicals Versatile Solutions for Construction and Consumer Goods](/upload/file/lifein-lgchem/PVC_LP_main.jpg)

![[PVC] Playroom mats with excellent shock absorption PVC Polyvinyl Chloride LG Chem Petrochemicals Versatile Solutions for Construction and Consumer Goods](/upload/file/lifein-lgchem/PVC_Mat_main.jpg)

![[PVC] Staying fit with gym balls PVC Polyvinyl Chloride LG Chem Petrochemicals Versatile Solutions for Construction and Consumer Goods](/upload/file/lifein-lgchem/PVC_Gymball_main.jpg)

![[PVC] Making rafting boats lighter PVC Polyvinyl Chloride LG Chem Petrochemicals Versatile Solutions for Construction and Consumer Goods](/upload/file/lifein-lgchem/PVC_boat_main.jpg)

![[PVC] Creating a festive atmosphere with Christmas tree PVC Polyvinyl Chloride LG Chem Petrochemicals Versatile Solutions for Construction and Consumer Goods](/upload/file/lifein-lgchem/PVC_tree_main.jpg)